Sustainable Practices for Exhibitors at Natural Products Expo West

As one of the industry’s most anticipated gatherings, Natural Products Expo West provides a prime platform for exhibitors to showcase their commitment to sustainability. For exhibitors, sustainable practices at Expo West aren’t just about meeting attendee expectations but also about reinforcing brand values and contributing to the natural products industry’s larger mission of environmental stewardship. Here’s how exhibitors can implement sustainable practices in preparation for the show and on the expo floor.

Pre-Show: Planning a Sustainable Exhibit

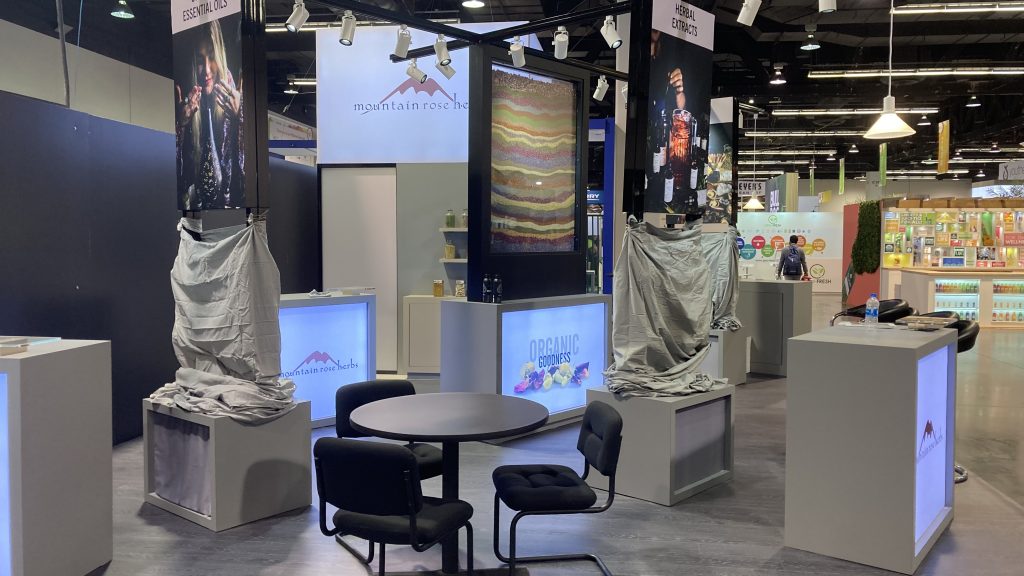

The journey toward sustainability begins well before the show opens. Start by designing a booth that uses eco-friendly materials. Many exhibitors are moving toward modular displays crafted from recycled or repurposed materials, which minimize waste and provide durability for future shows. Seek out materials like bamboo, reclaimed wood, and fabrics made from recycled fibers to give your exhibit a sustainable edge without sacrificing visual appeal.

Consider also the efficiency of shipping. Compact, modular designs reduce packaging waste and lower carbon emissions during transit. Another option is partnering with local vendors for booth assembly and supplies, which reduces the carbon footprint associated with transporting materials from afar. Some exhibitors are also exploring digital-only handouts to lessen the need for printed materials, instead using QR codes or email follow-ups to share product details.

Finally, when planning giveaways, go for practical, sustainable items that align with your brand ethos. Reusable water bottles, recycled notebooks, or plant-based packaging are great choices that reinforce an eco-conscious message.

At the Show: Practicing Sustainability on the Expo Floor

Once the booth is set up at Natural Products Expo West, there are numerous ways to continue with sustainable practices. First, limit single-use plastic by providing reusable items or compostable alternatives. If you’re offering samples, use plant-based or biodegradable containers to reduce waste.

Engage with attendees through digital touchpoints whenever possible. Instead of brochures, consider using iPads or touchscreen displays to show product information, allowing visitors to email materials directly to themselves, thus reducing paper waste.

Additionally, implement energy-efficient lighting options to reduce electricity consumption in your booth. LED lights not only save energy but can also create a vibrant, welcoming space for attendees.

At the end of the show, commit to a zero-waste breakdown strategy. Many exhibitors arrange for leftover materials and samples to be donated to local charities or repurposed, preventing them from heading to the landfill. You can also coordinate with the expo’s sustainability initiatives to dispose of materials responsibly.

Lead by Example

As an exhibitor at Natural Products Expo West, sustainable practices can help you stand out and demonstrate your dedication to the natural products industry’s core values. By adopting eco-friendly practices before and during the show, you can minimize environmental impact while strengthening your brand’s commitment to a greener future.

Check out our selection of Eco-Friendly tradeshow booths! Here are our ISLAND DESIGNS and our INLINE DESIGNS.